Inside your computer, the storage drive (whether an SSD or an HDD) works alongside your system’s memory and processor to access and use data. Solid state drives use different technology than traditional hard drives that allow SSDs to access data faster, improving your computer’s performance. This data includes things like your operating system, games, images, or music.

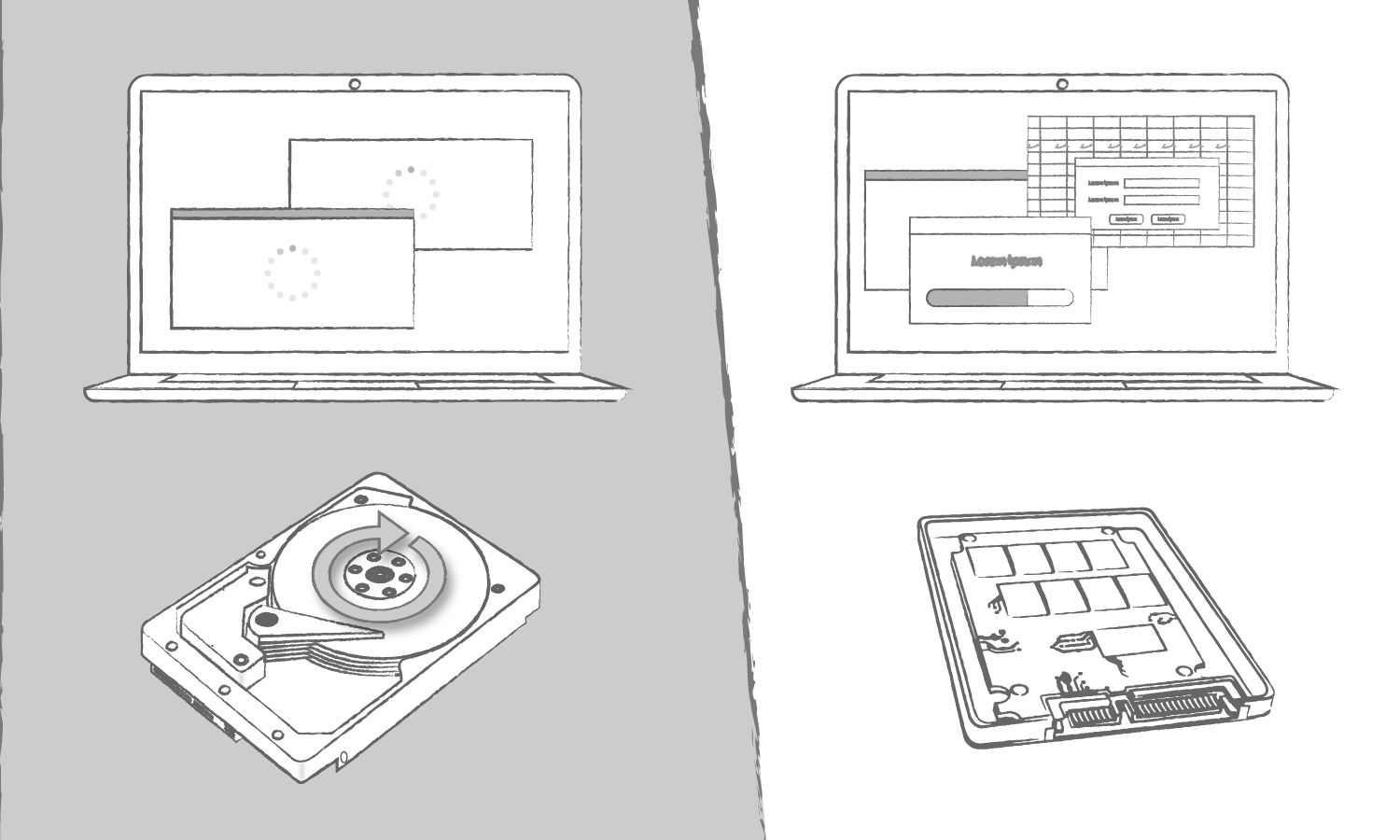

For example, if you want to access data from a spreadsheet and perform some edits, here’s what’s going on behind the scenes:

1. Programs and files are stored on your storage drive. In this case, the spreadsheet you want to access.

2. When you make a request to open the spreadsheet, your computer’s processor (CPU) transfers the program data from your storage drive to RAM for short-term access and use. Check out my blog on RAM here. Because SSDs have nearly-instant data transfer speeds, they speed up the data transfer process, which is the amount of time it takes to load programs and files.

3. The processor then accesses data from the memory, which acts as your computer’s bank of available workspace. Memory is then used to run the program.

For example, if you want to access data from a spreadsheet and perform some edits, here’s what’s going on behind the scenes:

1. Programs and files are stored on your storage drive. In this case, the spreadsheet you want to access.

2. When you make a request to open the spreadsheet, your computer’s processor (CPU) transfers the program data from your storage drive to RAM for short-term access and use. Check out my blog on RAM here. Because SSDs have nearly-instant data transfer speeds, they speed up the data transfer process, which is the amount of time it takes to load programs and files.

3. The processor then accesses data from the memory, which acts as your computer’s bank of available workspace. Memory is then used to run the program.

Solid state drives use flash memory to deliver superior performance and durability. Because there are lots of small, moving parts inside your hard drive — magnetic heads, spindles, and spinning platters — it's easy for things to go wrong and you could lose your important data. Without moving parts, SSDs are more durable, run cooler and use less energy.

SSDs function like hard drives, but with different technology. Like USB drives, SSDs use flash memory to store data, which is accessed digitally. A hard disk drive (HDD) uses a spinning platter and an arm that moves across the platter to read each portion of data. As a result, SSDs deliver nearly-instant boot and load times because they don’t have to mechanically seek out data on a spinning platter.

Form Factors

2.5-Inch SSD

mSATA SSD

M.2 SSD

2.5-Inch SSD

The standard form factor for an SSD is 2.5-inch, which fits inside the drive bay of most laptop or desktop computers. Because many users replace their hard drives with solid state drives, the 2.5-inch drive has become a standard for all HDDs and SSDs. They are designed to minimize the need to replace the connecting interface cables, making the transition to a higher performance drive as easy as possible.

mSATA SSD

A smaller form factor SSD is called mSATA. mSATA SSDs are one-eighth the size of a 2.5-inch drive and are designed to plug into an mSATA socket on a system’s motherboard. mSATA drives are used in ultra-thin and mini devices, or as a secondary drive in desktops.

M.2 SSD

The smallest form factor for SSDs is called M.2, which is about the size of a stick of gum. M.2 SSDs attach to the motherboard via an M.2 socket and are designed for space-constrained tablets and ultrabooks.

How NAND Works

Form Factors

2.5-Inch SSD

mSATA SSD

M.2 SSD

2.5-Inch SSD

The standard form factor for an SSD is 2.5-inch, which fits inside the drive bay of most laptop or desktop computers. Because many users replace their hard drives with solid state drives, the 2.5-inch drive has become a standard for all HDDs and SSDs. They are designed to minimize the need to replace the connecting interface cables, making the transition to a higher performance drive as easy as possible.

mSATA SSD

A smaller form factor SSD is called mSATA. mSATA SSDs are one-eighth the size of a 2.5-inch drive and are designed to plug into an mSATA socket on a system’s motherboard. mSATA drives are used in ultra-thin and mini devices, or as a secondary drive in desktops.

M.2 SSD

The smallest form factor for SSDs is called M.2, which is about the size of a stick of gum. M.2 SSDs attach to the motherboard via an M.2 socket and are designed for space-constrained tablets and ultrabooks.

How NAND Works

SSDs can be thought of as large USB drives; they use the same base technology. NAND, the technology in solid state drives, is a kind of flash memory. At the lowest level, floating gate transistors record a charge (or lack of a charge) to store data. The gates are organized in a grid pattern, which is further organized into a block. Block size can vary, but each row that makes up the grid is called a page.

An SSD controller that performs several functions, including keeping track of where data is located.

Reading and Writing on SSDs

Updating data is more complex for SSDs. All the data in a block must be refreshed when any portion of it is updated. The data on the old block is copied to a different block, the block is erased, and the data is rewritten with the changes to a new block.

Each time you ask your computer to retrieve or update data, the SSD controller looks at the address of the data requested and reads the charge status.

When the drive is idle, a process called garbage collection goes through and makes sure the information in the old block is erased and that the block is free to be written to again.

There is another process, called TRIM, that informs the SSD that it can skip rewriting certain data when it erases blocks. Because there are a finite number of times any block can be rewritten, this is an important process that prevents premature wear on the storage drive.

To further prevent wear on the drive, there is an algorithm to make sure that each block in the drive gets an equal amount of read/write processes. This process is called wear leveling and happens automatically as the drive is working.

Because the read/write process requires data movement, SSDs are usually over provisioned with storage; there is always a certain amount of the drive that is not reported to the operating system, and not accessible to the user. This allows room for the drive to move and delete items without affecting the overall storage capacity.

Manufacturing

Micron manufactures solid state drives from the ground up. Every step of the process is handled in-house, from creating flash media out of silicon wafers to building printed circuit boards to assembling the finished products. They then test the products rigorously for quality and reliability before shipping them to customers all over the world.

Solid state drives use flash memory chips to store information, an SSD is made of several memory chips installed on a circuit board. Micron manufactures the flash memory chips in‑house on silicon wafers, similar to how Micron makes its computer memory.

Because the silicon wafers are susceptible to contamination, robots move the wafers through more than 800 operations, which take more than a month to complete. As the wafers move through the process, many layers of materials are added to the wafer. These include conductive materials such as copper and non-conductive materials like silicone dioxide. After each layer of material is applied, the wafer is coated with light-sensitive fluid, then ultraviolet light is flashed on to it through a glass stencil of the electrical circuitry pattern. Where the light contacts the materials, they break down and dissolve. Where the materials are shielded by the stencil, they remain intact, which prints the circuitry pattern on the wafer. Chemical baths then wash away any residual material.

After printing, each 30-centimeter wafer yields hundreds of chips, which must be sliced apart. After the chips are cut apart, they are inserted into a protective plastic housing.

Large circuit boards are covered with tin alloy solder paste in the areas the memory chips and other components will be attached. A robot attaches the components to the board, then the assembled boards go into an oven that fuses the components to the board.

Quality Control

The boards first go through an optical scan to verify that the components on the board are in the correct place, then the next machine x-rays the board to ensure that everything is soldered in the correct place. The large circuit boards are now cut into individual boards and, in the case of a 2.5-inch drive, inserted into plastic housing.

Every drive is then labeled with its model and serial numbers, technical specifications, and other information. One other piece of information is a barcode for production tracking. The drives are plugged into a tester to verify functionality and install the firmware that runs the drive. The drive then undergoes up to 60 hours of performance testing to ensure that it stores data correctly and reads and writes at target speeds. Micron's SSDs are also tested with a variety of motherboards to ensure widespread compatibility.

The drives are then packaged with a foil pouch to avoid static electricity, and placed in a carton. From there, they are sent anywhere in the world.

Advantage of having an SSD

With traditional hard drives, the continuous motion generated by small moving parts creates heat, which is a leading factor in hard drive failure. Because SSDs don't have moving parts, they're more reliable and more shock-resistant than traditional hard drives. They're also more resistant to common drops, accidents, and wear and tear because they don't have the small, damage-susceptible parts of traditional hard drives. If you happened to drop your laptop and it had an SSD installed, your screen would probably break before the SSD.

Without moving parts to slow your computer down, SSDs aren't just faster; they're ready to go when you are. SSDs offer instant-load performance, meaning faster boot times, faster application loading times, and better system responsiveness.

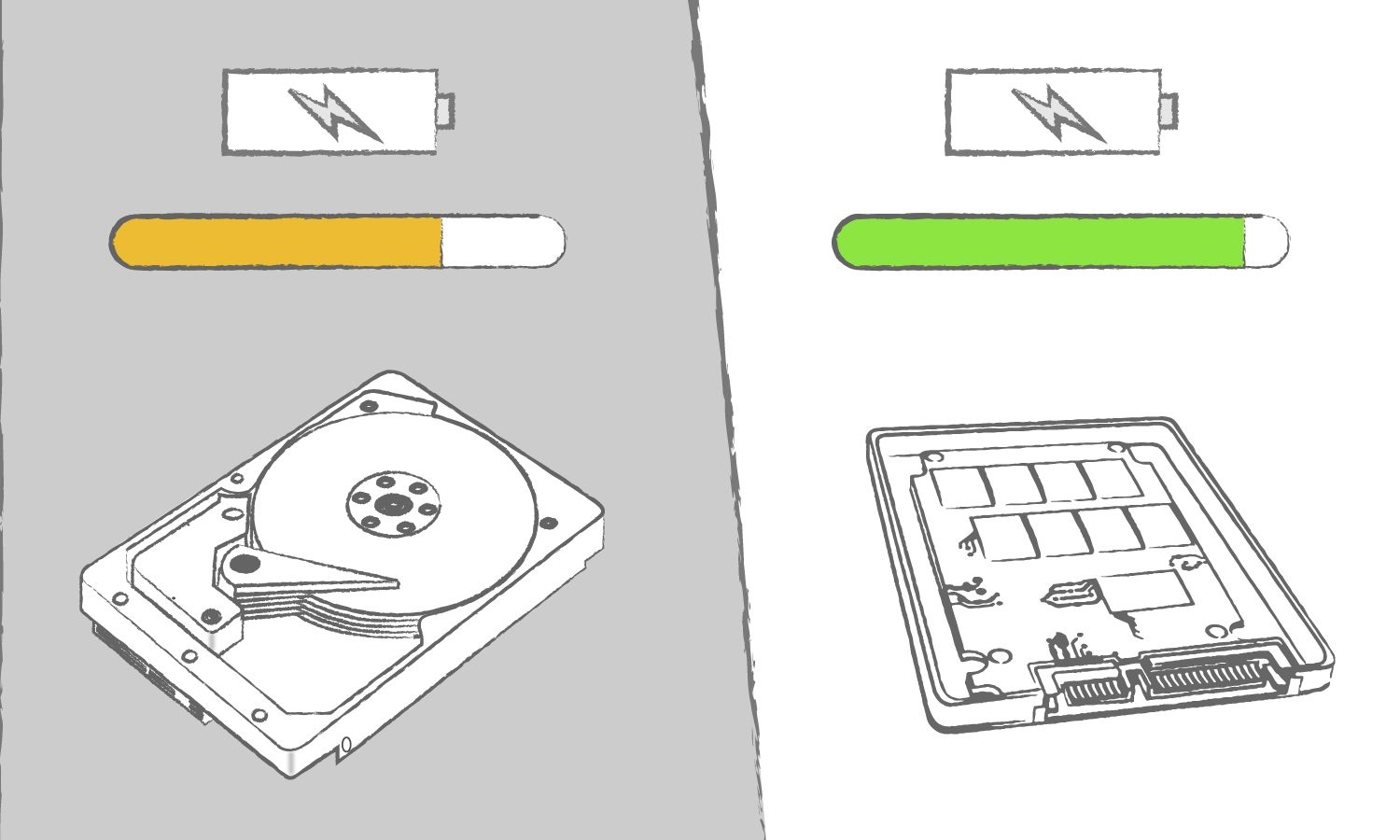

Because SSDs weigh less than hard drives, they're more mobile-friendly; making your laptop lighter and easier to carry. With lightweight components and solid construction, SSDs are better suited for the rigors of constant travel. An advantage of SSDs is that they have no moving parts, as a result, they require less power to operate, which means you'll get longer battery life. They're even quieter, too.

Here are some videos to help you learn more: